|

Introduction to Laser Cutting

Goals

In this chapter, we will explain how a laser cutter works and its' basic applications.

Content in a nutshell

- A laser cutter is a type of CNC (Computer Numerical Controlled) machine that uses a laser beam to precisely cut or engrave materials. There are different types of laser cutters depending on their operating power. Gas lasers and CO2 lasers in particular are the types that are now commonly used by hobbyists and small businesses. Other types are for example fiber or crystal lasers which are mostly used for industrial applications.

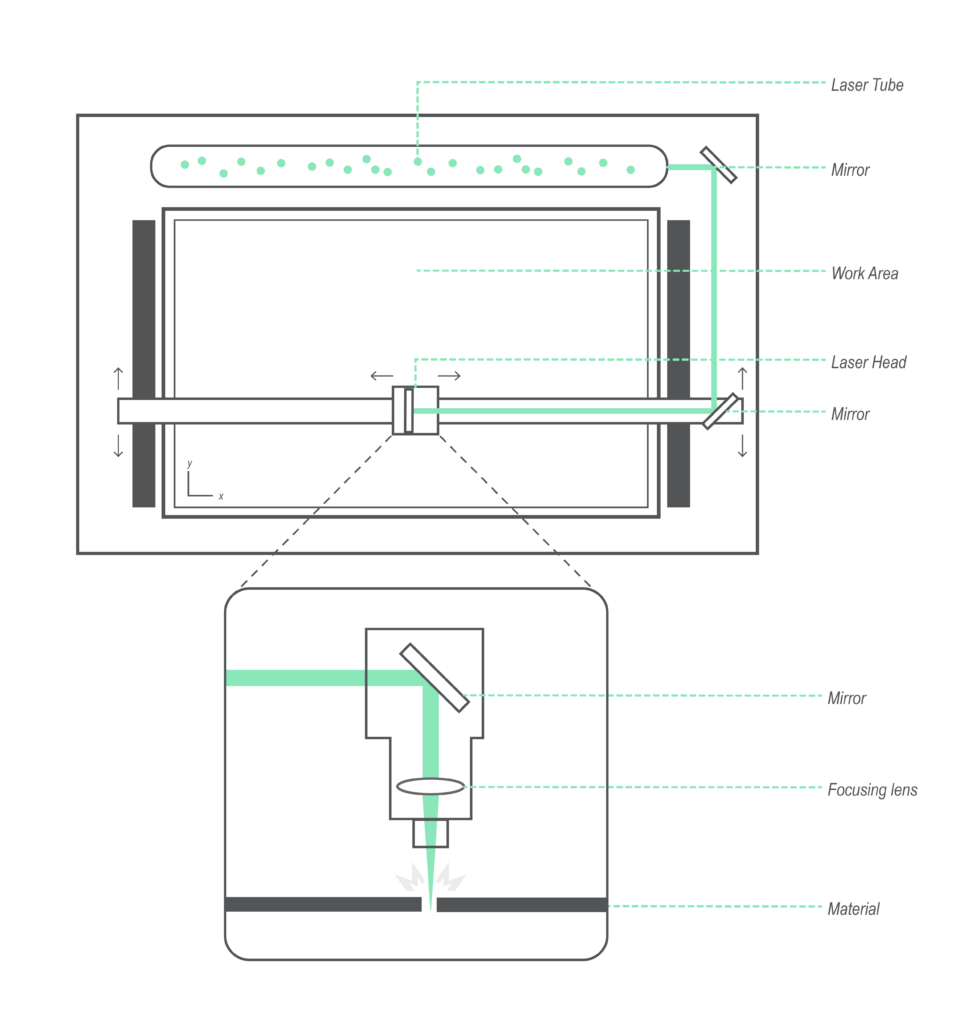

- Although there exist a handful of different types of laser cutters, they essentially use the same process to cut or treat the material. A laser resonator sends out a beam of intense light which reflects through a system of mirrors to the laser cutting head, where the laser is focused through a lens to an extremely thin, concentrated beam that can then cut or raster the surface of a material.

- It is possible to cut, engrave and mark a variety of materials with a laser cutter.

What is a Laser Cutter?

A laser cutter is a type of CNC (Computer Numerical Controlled) machine that uses a laser beam to precisely cut or engrave materials.

The term “Laser” is an acronym for “Light Amplification by Stimulated Emission of Radiation”. In colloquial terms, a laser is simply a highly focused, highly amplified beam of light. The laser beam causes the material it touches to locally Burn, melt or vaporize. The kind of material that a laser can cut depends on the type of laser and the strength of a specific machine.

There are different types of laser cutters depending on their operating power. Gas lasers and CO2 lasers in particular are the types that are now commonly used by hobbyists and small businesses. Other types are for example fiber or crystal lasers which are mostly used for industrial applications. CO2 laser cutters are capable of cutting and engraving a wide range of non-metallic materials such as wood, paper, acrylic, textiles, and leather. Industrial lasers on the other hand, like Neodymium and Fiber Lasers, have a much higher intensity, and can thus cut through much thicker, stronger materials.

How does a Laser Cutter Work?

Although there exist a handful of different types of laser cutters, they essentially use the same process to cut or treat the material.

A laser resonator sends out a beam of intense light which reflects through a system of mirrors to the laser cutting head. Within the cutting head, the laser is focused through a lens and narrowed down to an extremely thin, concentrated beam. This beam can then cut or raster the surface, depending on the output strength and frequency.

The cutting head is mounted on a mechanical system that allows precise movement in an XY coordinate system, called an XY gantry. It allows the cutting head to precisely access all possible points within a rectangular boundary area, which defines the work bed of the cutter.

In order for the laser to cut efficiently, the focal point of the lens needs to be set to the surface of the material being cut. This requires an initial calibration of the laser head that we will talk about in one of the following chapters.

What Can Be Done With a Laser Cutter?

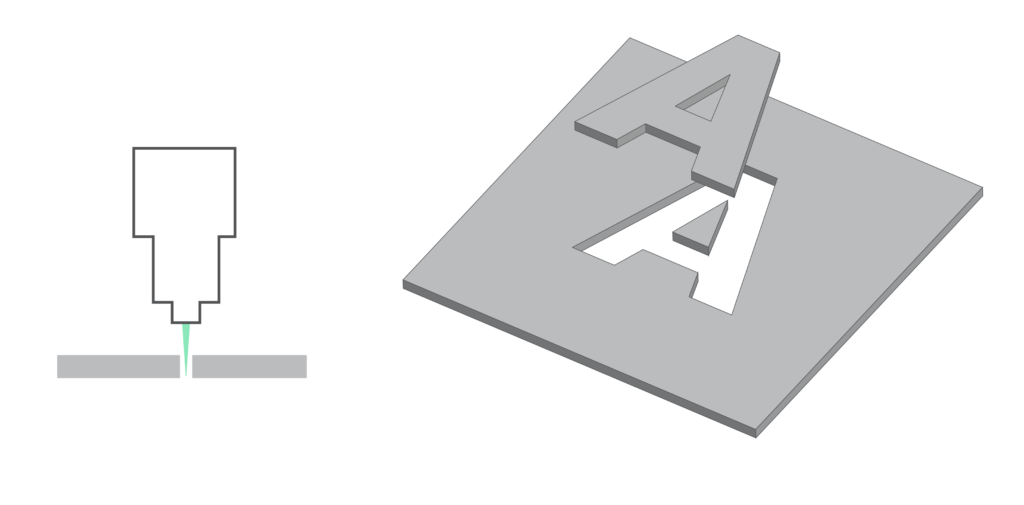

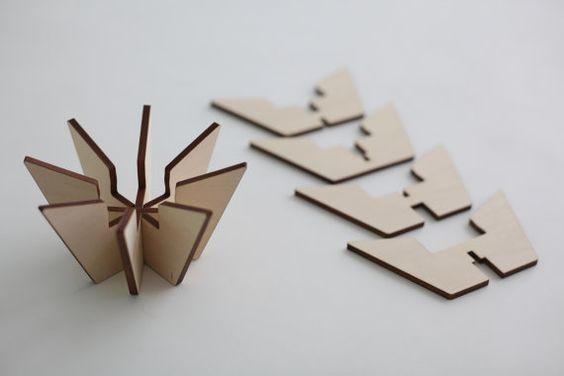

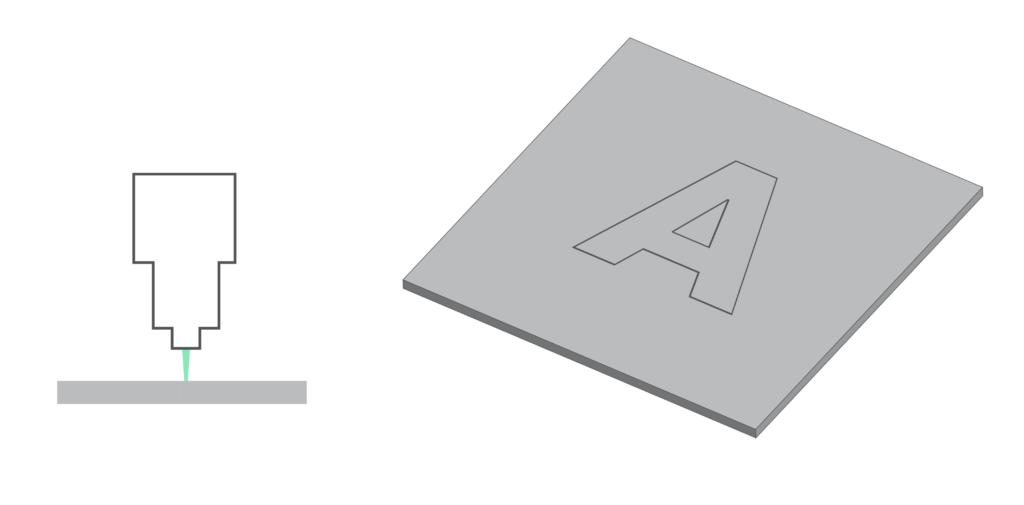

Cutting

When the output power of the laser is high enough it can effectively cut through certain materials.

Since the beam itself is very thin, the cut is in most cases precise and allows for design in very fine detail. Likewise, the kerf of a laser cutter is much thinner than the kerf of a saw blade or a milling bit. The term kerf refers to the width of the groove made while cutting.

[Image courtesy of 'Tokyo craft Studios']

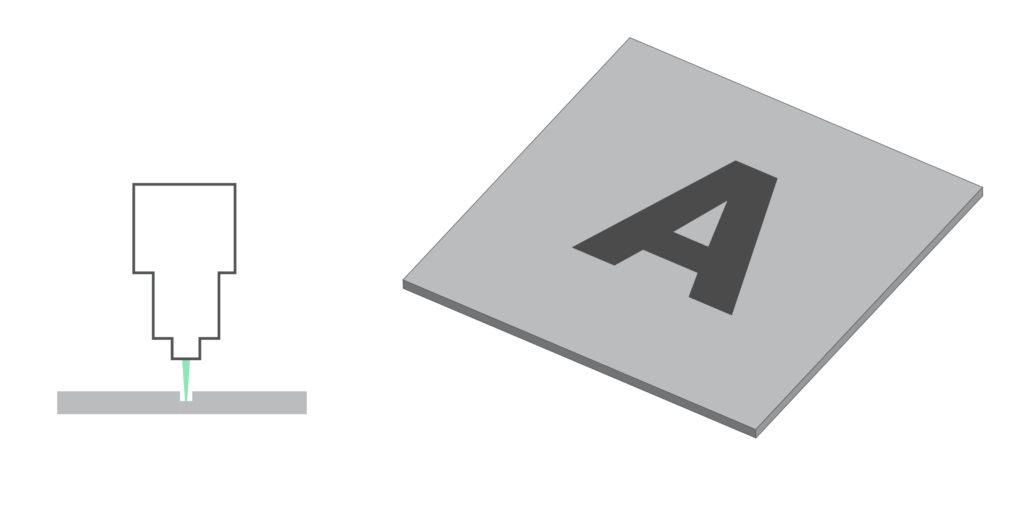

Engraving

Engraving is when the laser burns off only the top layer of the material and doesn't cut all the way through.

This can be achieved by either adjusting the power and speed setting of the laser head (vector/linework images) or by using laser rastering (raster images), a technique that will be explained in more detail in the following chapter.

Example of layering engraved Acrylic panels to create a transparent topography effect. [Image courtesy of Ho Jin Teck from FormAxioms Studio]

Marking

Marking is a treatment where the laser does not remove the top part of the material but, still changes the surface properties of the material.

With CO2 laser cutters marking is most often used when working with metals, as the output power is not high enough to effectively cut or engrave them. The surface of the workpiece is coated with a chemical called a marking solution, such as CerMark or Enduramark, that reacts and bonds chemically to the metals' surface when exposed to a laser beam. Choosing a particular marking solution will result in a different quality of the mark left on the metal in terms of color and durability.