Introduction to 3D Printing

Goals

We will examine the basics of 3D printing: what it is and its possible applications. We will explain some of the terminology used in the field, as well as its benefits and limitations.

Content in a nutshell

- 3D printing is an additive fabrication method where artifacts are “printed” or assembled from a granular or melted material particle by particle

- Benefits: Geometry complexity, low cost, multiple iterations, and small scale

- Limitations: Low strength and durability, small scale series, and limited accuracy and tolerances

Definition

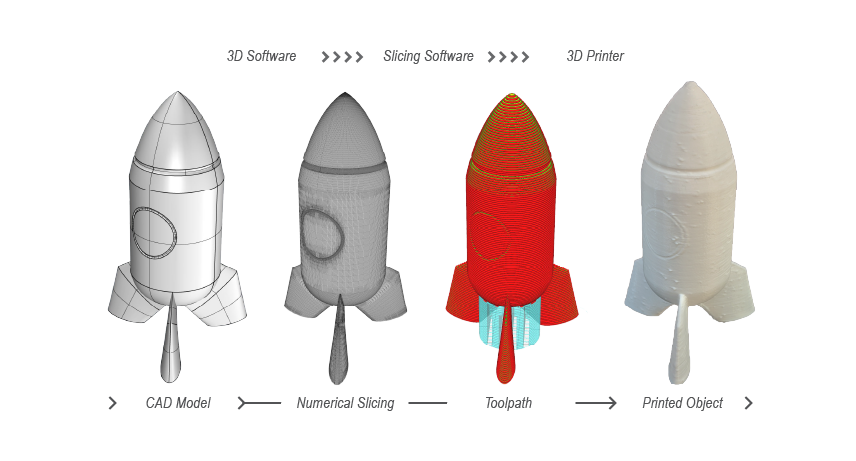

3D printing is a prototyping technology where a digital model is turned into a three-dimensional object by adding material – generally layer by layer, through a computer-controlled tool.

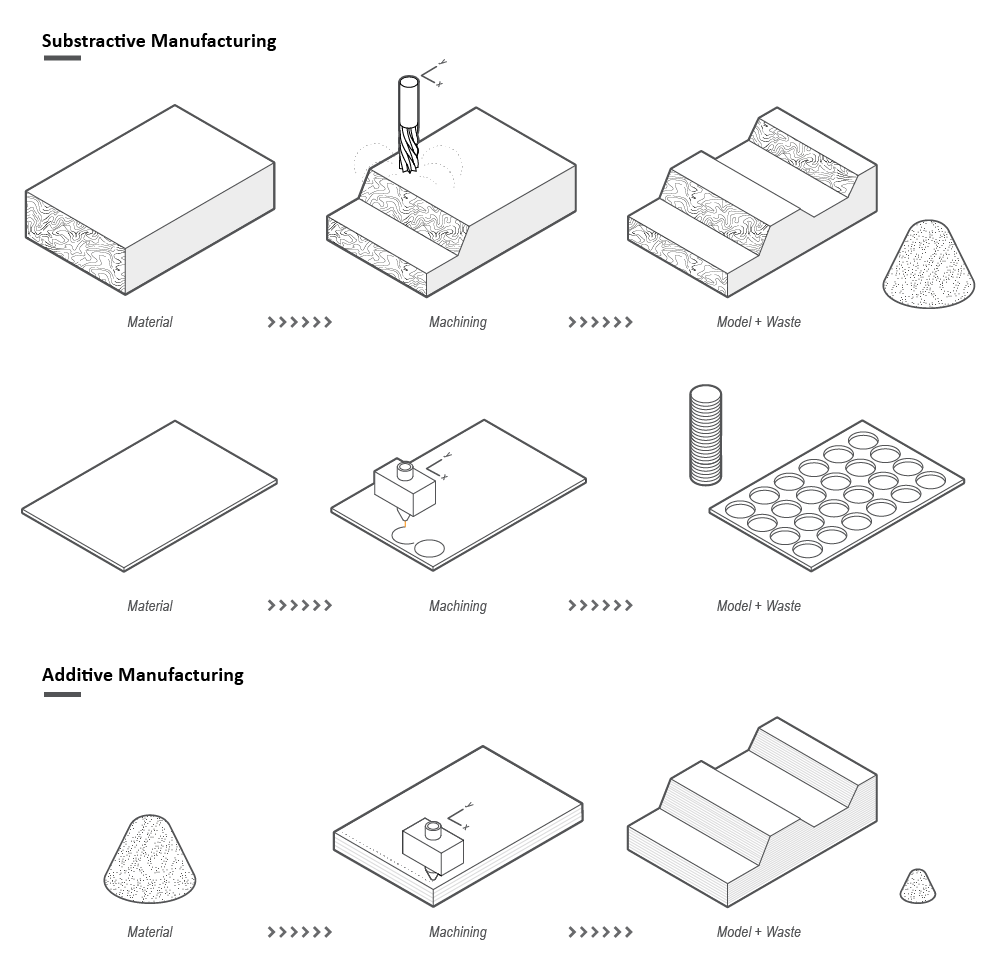

3D printing is different from other manufacturing technologies such as CNC machining or mold casting/injection because it neither subtracts material nor requires building special tools, such as carving tools or molds for machining. Instead, it is possible to build almost any 3D object onto a platform by adding material in layers.

Contrary to popular belief, 3D printing is not a new technology.

It was developed in 1986 by a company called 3D Systems and initially called Stereolithography (STL) but it remained a very expensive technology, mostly used in industrial settings. In 2009, the patent for the technology expired, which led to the birth of low-cost desktop printers, including the development of open-source printers. During the last 10 years, its popularity has increased greatly due to its affordability, possibilities of use, and constant development.

Characteristics and use

Using a 3D printer requires the knowledge of computer-aided design (CAD modeling) and an understanding of the process in the graphic above. All 3D printers follow this process, but depending on the type of technology used, the way they do it is different: For example, a material extrusion printer (called FDM or FFF printers) uses a plastic filament that is melted through a heated nozzle and deposits it on a platform layer by layer. SLA printers use a laser to harden (cure) thin layers of photo-reactive polymer onto a platform.

Today, 3D printing is used in a wide range of applications: from the development of quick prototypes for product design and engineering to the use in industrial manufacturing of small-scale series, sculpture, animation, ceramics, and even fashion. Although plastic is the most widely used material, it is also possible to print with a variety of other materials, such as water-soluble polymers like PVA, clay, metal, cellulose, and even food. Depending on the technology and material used, printed parts can also have a wide range of physical properties, like being high-temperature resistant, clear, or flexible. In some cases, to achieve a particular surface finish, it is necessary to post-process the printed part (sanding, painting, polishing).

Benefits and Limitations

Benefits

- Geometry complexity: It is possible to create geometries that otherwise would be impossible to manufacture with traditional prototyping methods.

- Low cost: Production of 3D printed small series is sometimes less expensive compared to traditional fabrication methods. 3D printing technology is continuously becoming more affordable and widespread. Materials with high technical characteristics can be purchased at low costs. In the same fashion, it is possible to produce single pieces without having to print a complete series of them.

- Multiple iterations: 3D printing speeds up the iteration process in the design of parts and pieces. It also reduces the time of prototyping, avoiding the need of multiple tools and molds in order to achieve a precise model.

- Dimension: Depending on the type of technology used, it is possible to print very small-scaled parts, up to a cubic meter of volume. There are even examples of houses and buildings being printed.

Limitations

- Low strength and durability: Printed parts, especially plastic ones, are not as strong and durable and their CNC'd and mold injected counterparts. Material extrusion (FDM of FFF) parts tend to break when put under high stress horizontally, and sun and humidity can alter their physical properties.

- Small scale series: 3D printing is suitable for printing small-scale series - perhaps in the scale of tenths. 3D printing is not suitable for fabricating larger series (in the hundreds or thousands). The price would exceed fabrication with another method, because of the long fabrication time and material costs.

- Limited accuracy and tolerances: Although permanently improving, 3D printers are still not able to produce a 100% accurate piece in its dimensions. Even with the most advanced technologies, there will always be a small dimension tolerance.